Sticky Roller

Sticky Roller

Manufacturing of sticky roller and coating process for board clean machine.

Acid and alkali resistant, heat resistant, long service life.

Removal of dust, lint, copper chips and other contaminants.

Specifications can be made according to customer’s requirements.

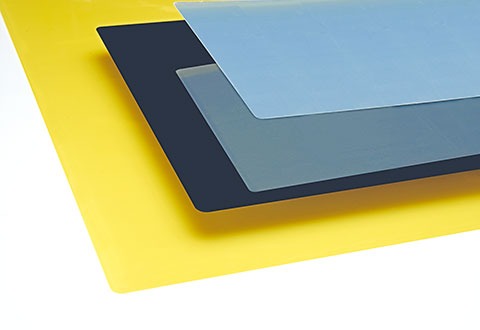

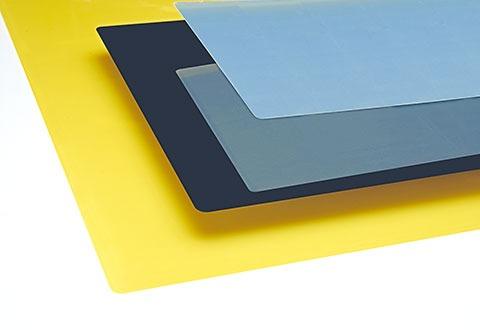

Multi-functional cleaning plate

Multi-functional cleaning plate

Corresponding process:

1.Pre-processing line

2.Developing Line

3.Etching Line

4.Stripping Line

5.Drilling Line

6.Copper plating Line

7.A/W (artwork)room dry filmmolding press

8.Automatic Mask Aligner

Function:

1.Clean the foreign matter, dust, ink sludge and ink chips from the conveyor rollers

2.Sticky suspended particles in the indoor air.

3.Clean particles from circulating air in the oven.

4.Carries small sheets of Flexible Printed Circuit (FPC) and Thin printed circuit board.

5.Thermal compression bonding roller cleaning

6.Dry process transport cleaning

Ingredients:

Polymers, fiberglass board.

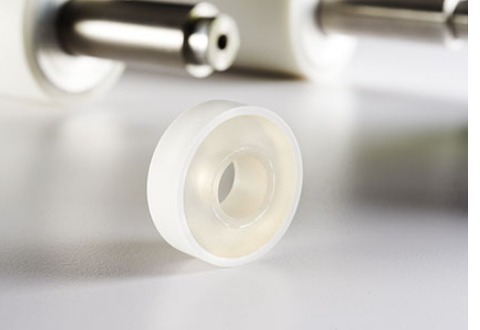

Dust roller

Product Design:

1. The resin is made of special composite material, which has excellent weather resistance, high temperature resistance and friction resistance, and does not change the molecular structure and physical properties after wiping to ensure the long service life of the roller.

2. Low hardness, softer than sticky paper rolls, high adhesion, better adsorption of foreign objects.

3. Long time to maintain the foreign object adsorption ability, at least three months of service life.

4. No glue removal, residual glue and dusty paper rolls.

Advantages and usage:

1. Can completely replace the dust paper roll, saving cost and reducing waste.

2. No need to change equipment, it can be used directly on any dusting machine.

3. Without the use of sticky paper rolls, it can reduce the pressure of huge inventory and make more space in the warehouse.

4. Reduce the Dioxin generated by the paper rolls to tear off the waste, and save energy and love the earth.

5. Clean the surface and wipe with 75% alcohol and it will recover the adhesion.

Hand cleaner:

Adopt imported silicone material, passed SGS inspection to meet RoHS regulations.

The patented design of the handle is light and durable, easy to replace the rollers, and avoids the problem of peeling and flaking of the general manual sticky dust rollers.

High, medium, low and zero viscosity rollers are available, and the viscosity can be adjusted according to customer requirements.

In addition to 6″, 12″ and other general specifications of the roller length, we can also customize various lengths of hand cleaner (1cm to 75cm) according to customer requirements.

Hand cleaner special adhesive paper:

Special adhesive coating is used to avoid the problem of peeling off the adhesive layer.

We can make 50 sheets of binding paper or single sheet type of adhesive paper according to customer’s requirement.

There are three sizes:

21cm*33cm, 21cm*35cm and 24cm*35cm, all 50 sheets/book.

It is made of dust-free PEPA film substrate, applying Hi-Polymer base resin bonding layer and then coated with acrylic adhesive, and processed by anti-aging and high temperature resistance treatment, so that the normal working temperature of this product can reach 85℃, and the maximum temperature resistance can reach 130℃ without adhesive residue problem.

It is the most suitable for all kinds of demanding electronic and optoelectronic industry cleaning requirements.

• Acrylic resin layer has excellent dust collection effect and contains maximum dust collection capacity.

• Hi-Polymer base resin bonding layer is used to strongly link the PEPA film substrate and Acrylic resin layer to avoid residual glue or debonding problems of the resin layer.

• Anti-aging and high temperature resistant treatment, normal working temperature reaches 85℃, maximum working temperature can be up to 130℃.

• The bottom layer is coated with a special release layer to obtain the smoothest release effect and avoid the pulling of the lower layer when tearing off.

Application areas:

• Optical display : TFT-LCD, STN, TN, touch panel, light guide, polarizer, reflector, diffuser, glass substrate, optical acrylic and other substrate coating, lamination, film, printing, and other operations of the board surface cleaning.

• PCB: A/W (artwork) and substrate in each process such as cutting, laminating, exposure, printing, inspection and other operations of the board surface cleaning.