Why Choose Chun Yang Technology Color Sorters?

Chun Yang Technology offers a wide range of

industry-leading AI smart color sorters suitable for diverse applications

including tea leaves, hardware, plastics, and coffee beans. Powered by

high-precision CCD imaging, AI deep learning algorithms, and intelligent air

jet systems, these machines enable efficient, automated, and low-error sorting

processes. With a variety of sizes and full-featured designs, they are ideal

for both large-scale production lines and small factories.

Applicable Tea Types:

Black tea, green tea, white tea, oolong tea, West Lake Longjing, Tieguanyin, Da

Hong Pao, and more.

Key Highlights:

AI Smart Tea Leaf Color Sorter

一.Machine Overview

The AI Smart Professional Tea Leaf Color Sorter

adopts the latest AI deep learning system, replacing traditional color sorting

systems to meet the growing demand for personalized and highly refined sorting

requirements. Deep learning, a form of artificial intelligence (AI), enables

the model to recognize complex patterns in images, text, sound, and other

data—producing more accurate insights and predictions. The deep learning

algorithm enhances the traditional sorting method by more accurately analyzing

each tea leaf and effectively identifying and separating color differences,

leaf structures, impurities, and other difficult-to-detect elements. Multiple

sorting objectives can be completed in one pass.

二.Application Scope

This machine is suitable for sorting all

types of tea, including black tea, green tea, white tea, West Lake Longjing,

Tieguanyin, Da Hong Pao, Taiwanese oolong tea, and more.

三.Key Features

• Specially designed to separate stems, stalks, broken leaves, whole

leaves, and light impurities in finished tea products

• Fresh leaf sorting with precise control—color sorting, shape

sorting, and impurity sorting can all be easily handled

Chun Yang Technology provides a complete

set of support services:

Multifunctional Deep Learning Sorting

System

Core Technological Advantages

Equipped with an AI deep learning core algorithm, the ZB2-60 Smart Belt Color Sorter is Chun Yang Technology’s fully automated intelligent solution designed to meet the sorting needs of various particle materials, color differences, and impurities. From peanuts and soybeans to minerals and gemstones, this versatile machine delivers high-efficiency and high-precision sorting, making it an ideal automation upgrade for the food, agriculture, and industrial sectors.

ZB2-60 Machine Features

- AI Model Training Capability: Customizable sorting logic based on customer material

- Belt-Type Conveyor Design: High stability; suitable for irregular or fragile materials

- High-Efficiency Reject System: Precise ejection of impurities with minimal loss of good products

- Modular Design: Easy maintenance and quick parts

replacement

Applicable Materials

The ZB2-60 supports a wide range of

granular products across food, agricultural, and industrial raw materials:

Industries & Applications

High-Efficiency Particle Sorting|AI Deep Learning Technology

Smart Machine Overview

Chun Yang Technology proudly presents the next-generation M2-126 AI Smart Chute Color Sorter, featuring advanced deep learning algorithms and a high-precision vision system. It delivers fast, accurate sorting of various grains, nuts, and agricultural products, enabling one-pass impurity removal and significantly boosting production line efficiency and product quality.

Key Product Features

- High-Efficiency Chute Feeding Design: Ensures uniform material flow for stable and precise sorting

- Deep Learning Recognition Models: Self-learning capabilities for identifying various defect types with high accuracy

- Remote Operation & Maintenance: Real-time machine status monitoring reduces downtime risks

- One-Pass Sorting: Effectively removes color differences, misshaped items, and discolored impurities

- User-Friendly Interface: Touchscreen control for intuitive operation and fast setting adjustments

Applicable Materials

The M2-126 Chute Color Sorter is ideal for a wide range of medium-to-large granular materials, including:

Product Features:

DL30 Belt-Type Color Sorter

一.Machine Overview

The DL30 Color Sorter adopts the latest technology to

detect and automatically sort out defective particles from granular materials based

on their optical characteristics.

The sorting process starts when materials are fed into the machine through the

top hopper. Vibrating feeders ensure the materials slide down uniformly into

the observation area of the sorting chamber.

As the materials pass between the sensor and background plate under the

illumination of a light source, the system captures continuous images of

falling materials. Based on variations in brightness and color, the system

identifies differences and distinguishes good products from defective ones.

Compressed air is then used to eject defective items for precise separation.

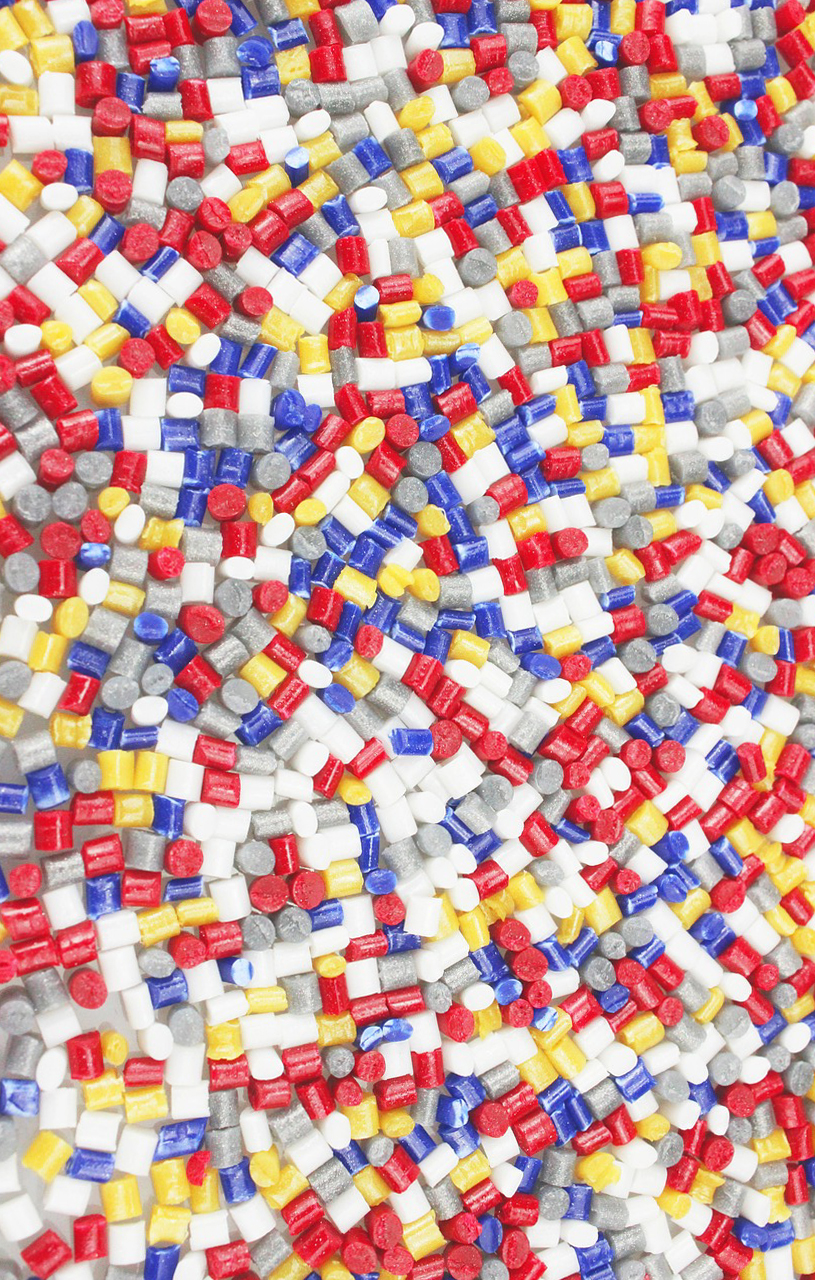

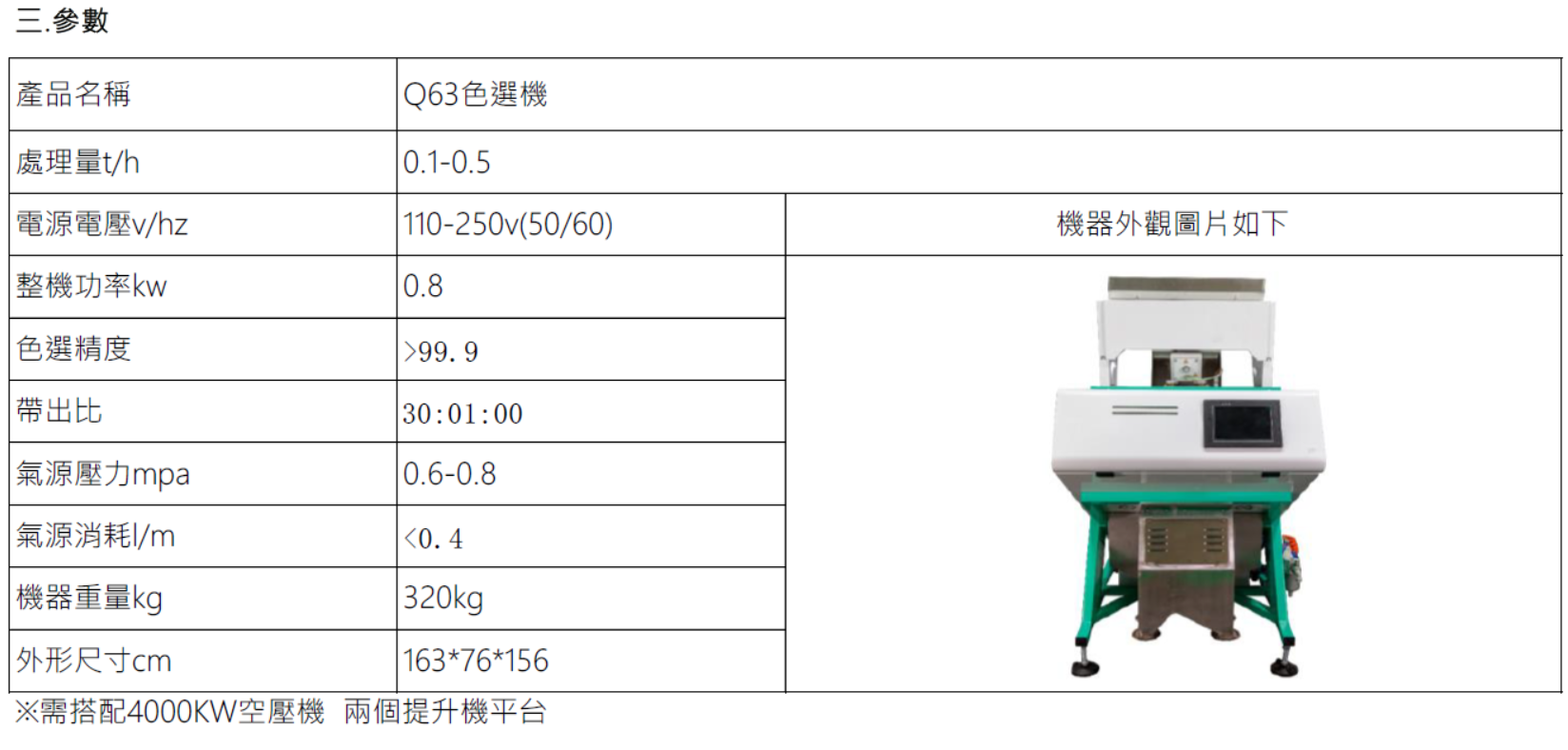

二. Application Scope

This machine is ideal for sorting hardware and

plastic materials.

三.Key Features

Application Scope:

Hardware parts, plastic components, and granular industrial materials.

Dual-Purpose for Food & Hardware

Machine Advantages:

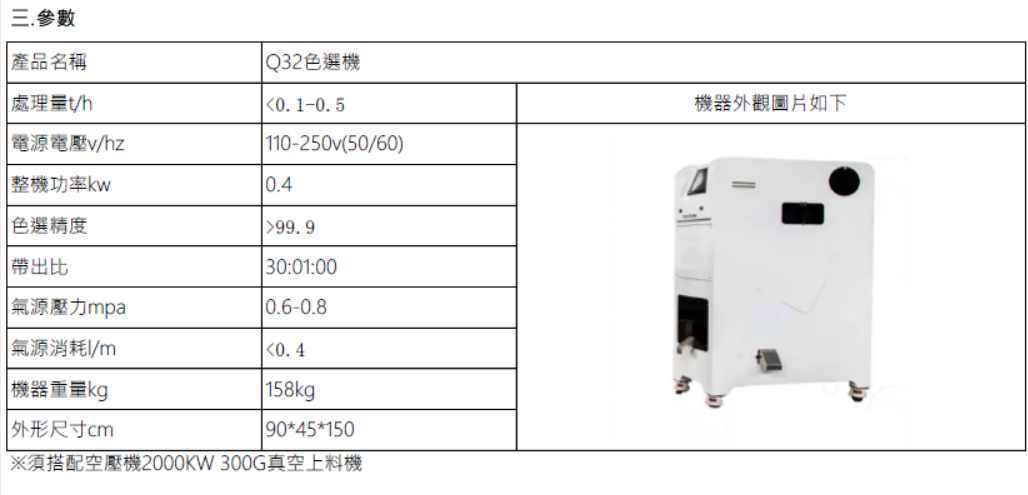

Q2 Specification Sheet

一.Machine Overview

Materials are fed from the top hopper into the sorter, where they slide down vibratory channels into the observation area of the sorting chamber. As they pass through the sensor and background plate under the illumination of a light source, the system continuously captures images of the falling materials.

Based on changes in light intensity and color, the system differentiates

between acceptable and defective items. Compressed air is used to eject

defective materials for accurate separation.

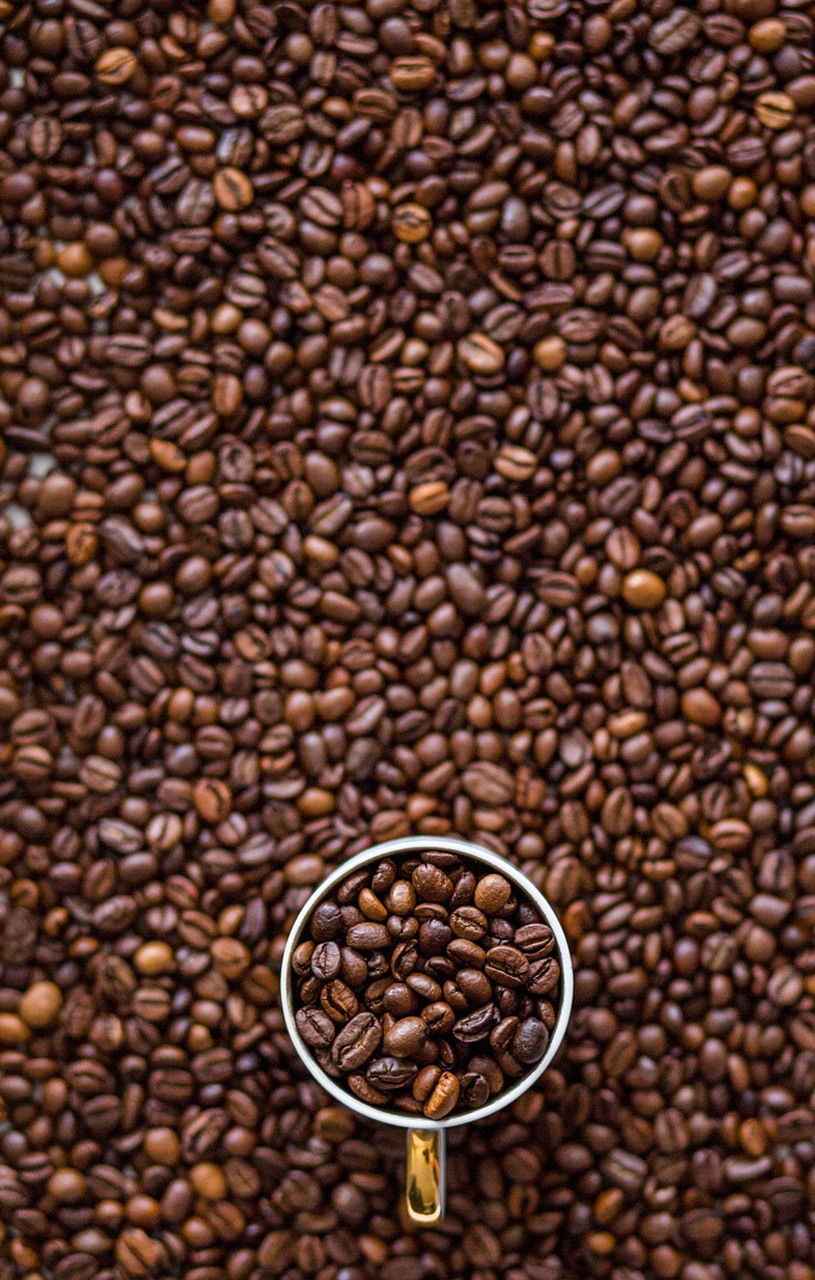

二. Application Scope

This machine is suitable for sorting coffee

beans, various grains, sesame, millet, rice, and hardware color materials.

三.Key Features

1. Intelligent air-jet rejection system; powerful shape-sorting capabilities; 3D recognition technology.

2.Visualized data analysis; advanced bionic-technology camera; ultra-high throughput capacity

Recommended Applications:

High-precision sorting for hardware and plastic materials.

Application Scope

This model is specifically designed for

sorting hardware and plastic materials.

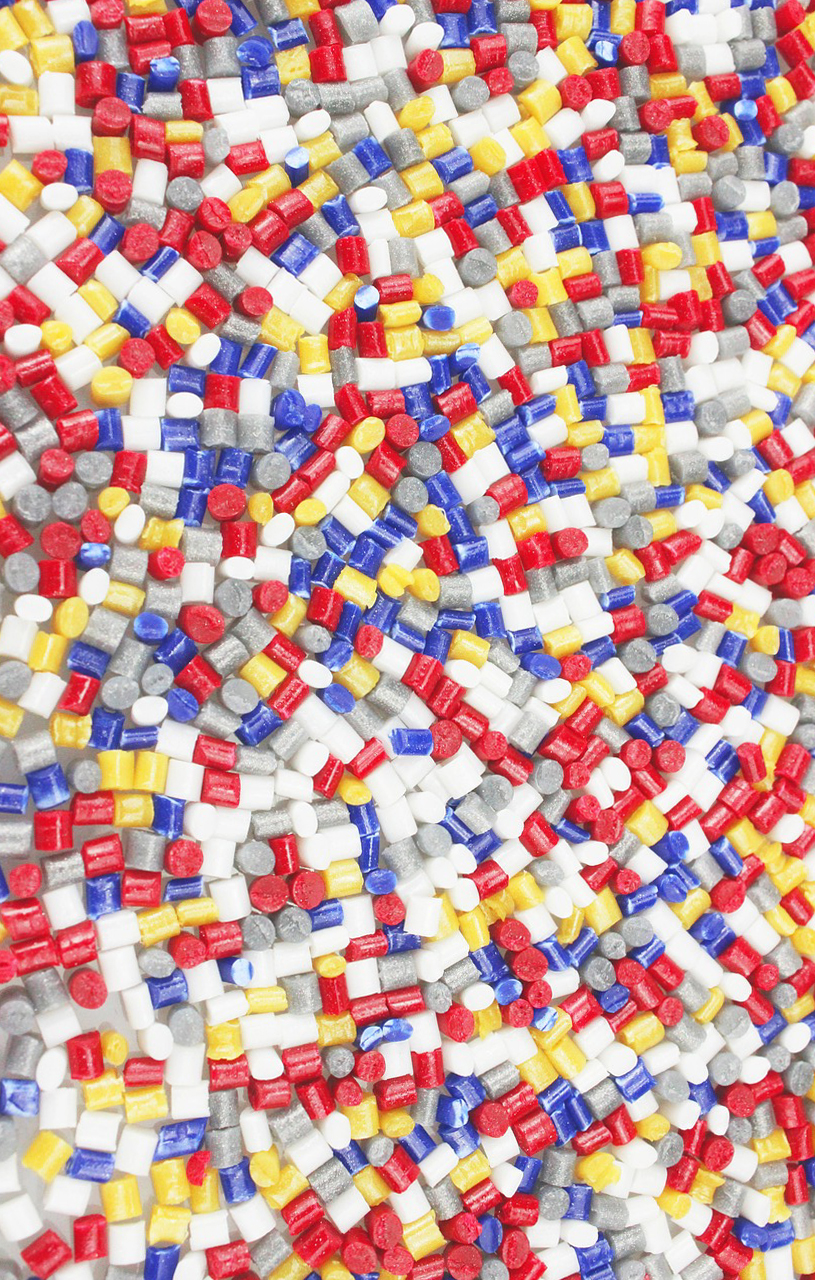

QHigh-End Industrial Sorting Platform

Product Highlights:

Q63 color sorter is a high-resolution CCD

and customized special color sorter lens, new rust-proof special sun and

chemical processing UV chute, RGB full color CCD camera, inside the monochrome,

bicolor, HS image processing algorithms, color selection and shape selection

technology combined with a minimalist interactive interface plus one-button

intelligent technology, the machine adopts the Japanese Toshiba sensors and

circuit IC and Japan's pneumatic and filtration components, the United States

Core Processor.

一.Q63 Color Sorter Technical Overview

1.The Q63 color sorter adopts the latest

technology to distinguish materials based on their optical characteristics.

2.It uses photoelectric detection to automatically

identify and remove defective particles from granular materials.

3.The working principle: Materials enter from the

top hopper and move through a vibrating device, sliding down the chute into the

sorting chamber.

4.In the observation zone, materials pass between

sensors and background plates under light exposure. Based on differences in

light intensity and color, the system continuously captures images, identifies

variations, and distinguishes between good and defective products. Defective

items are removed through a compressed air ejection system.

5.High-resolution CCD cameras paired with

customized color sorter lenses.

6.New rust-resistant UV-anodized chute design.

7.Full RGB true-color CCD imaging system, supporting single-color, dual-color, and HS (hue-saturation) image processing algorithms; integrates color and shape sorting technologies.

8.Simplified user interface with one-click intelligent control.

9.Equipped with Toshiba sensors, circuitry ICs,

Japanese pneumatic and filtration components, and U.S.-made core processors.

10.Intelligent ejection system, visualized

operational analysis, and innovative bionic camera technology.

11.Advanced shape sorting capability, 3D

recognition, and ultra-high throughput capacity.

Application Scope

This machine is suitable for sorting coffee

beans, plastic materials, hardware components, and more.

Target Users:

Designed for small factories,

community-level production units, and retail spaces with limited room.

Compact-Sized Sorting Machine

Key Features:

一 Q32 Machine Description

1.The Q32 color sorter adopts advanced technology

to differentiate materials based on their optical properties. Using

photoelectric detection, it automatically identifies and removes defective

particles from granular materials.

2.Operating Principle: Materials are fed into the

machine through a top hopper and vibrated by a vibrator mechanism.

3.The materials slide down the channel and

accelerate into the sorting chamber’s observation zone, passing between sensors

and a background panel.

4.Under the illumination of the light source,

differences in light intensity and color trigger system responses. The machine

continuously captures images, identifies color deviations, and distinguishes

between acceptable and defective items.

5.Compressed air is used to eject defective

products for separation.

6.Equipped with high-resolution CCD cameras and

customized sorting lenses.

7.Features a newly designed rust-resistant

UV-anodized chute and RGB full-color CCD imaging system.

8.Supports single-color, dual-color, and HS

(hue-saturation) image processing, combining color and shape sorting

capabilities.

9.Minimalist interactive interface with one-touch smart operation.

10. Incorporates Japanese Toshiba sensors,

electronic ICs, pneumatic and filtration components.

11.U.S.-based core processor enables micro-level color sorting, automatic parameter optimization, and visual operation analysis.

12.Specifically engineered for compact environments—machine footprint under 1 square meter, making it space-efficient yet functionally complete.

Application Scope

Suitable for sorting coffee beans, plastic

materials, hardware components, and more.

Compact-Sized Sorting Machine

Key Features:

1.The Q16 color sorter adopts cutting-edge technology to detect differences in the optical properties of materials. Using photoelectric detection, it automatically identifies and removes defective particles from granular materials.

2.Working Principle: Materials enter the machine through the top hopper and are guided by a vibrating mechanism.

3.The selected materials slide down the chute and accelerate into the observation zone inside the sorting chamber, passing between the sensor and the background panel.

4.Under the illumination of the light source, variations in light intensity and color are detected. The system continuously captures images, distinguishes differences in material color, and classifies items as acceptable or defective.

5.Defective items are removed by a compressed air ejection system.

6.Equipped with high-resolution CCD cameras and customized optical lenses designed specifically for color sorting.

7.Features a newly developed UV-anodized, rust-resistant chute and a full RGB true-color CCD camera.

8.Supports single-color, dual-color, and HS (hue-saturation) image processing algorithms; integrates color and shape sorting technologies.

9.Simplified user interface with one-click intelligent operation.

10. Incorporates Japanese Toshiba sensors, circuit ICs, pneumatic and filtration components.

11.U.S.-based core processor enables precise micro sorting, automatic sorting parameter adjustments, and visualized operational analysis.

12.The machine is designed for compact spaces—ideal for small factories, retail shops, and community units. With a footprint under 1 square meter, it offers full functionality in a small size.