uLED Mass Transfer Carrier and Packaging Solutions

Optimized for Next-Generation Display

Technologies

Chunyang Technology offers a range of high-performance carriers for micro and mini LED mass transfer applications. From chip transfer, bonding, rework to precision alignment, our carrier platform meets the demanding requirements of high speed, high accuracy, and high yield in modern display manufacturing.

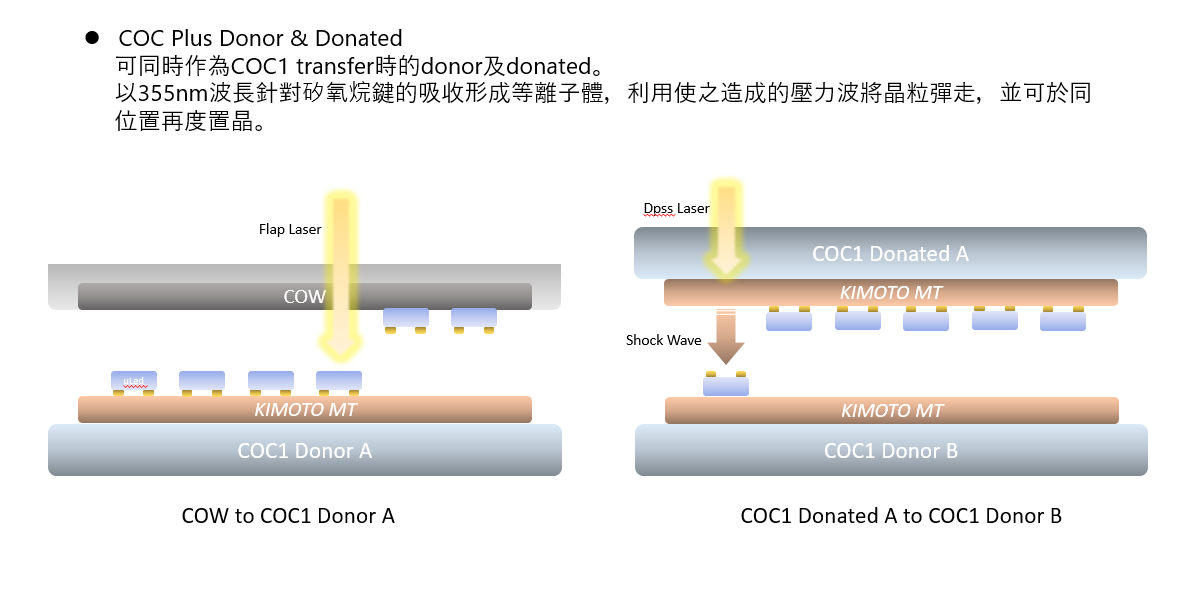

COC Plus Donor & Donated Carrier|Dual-Function Laser Transfer Platform

Key Features:

• Functions as both COC1 Donor and Donated carrier in a single

configuration

• Utilizes laser-induced pressure wave for efficient chip transfer;

supports repeated chip placement at the same location

• Ideal for high-precision laser transfer processes with full

automation and high-yield demands

Application

Scenarios:

• COC1-phase laser transfer for uLED manufacturing

• Microchip rework and repeat chip placement

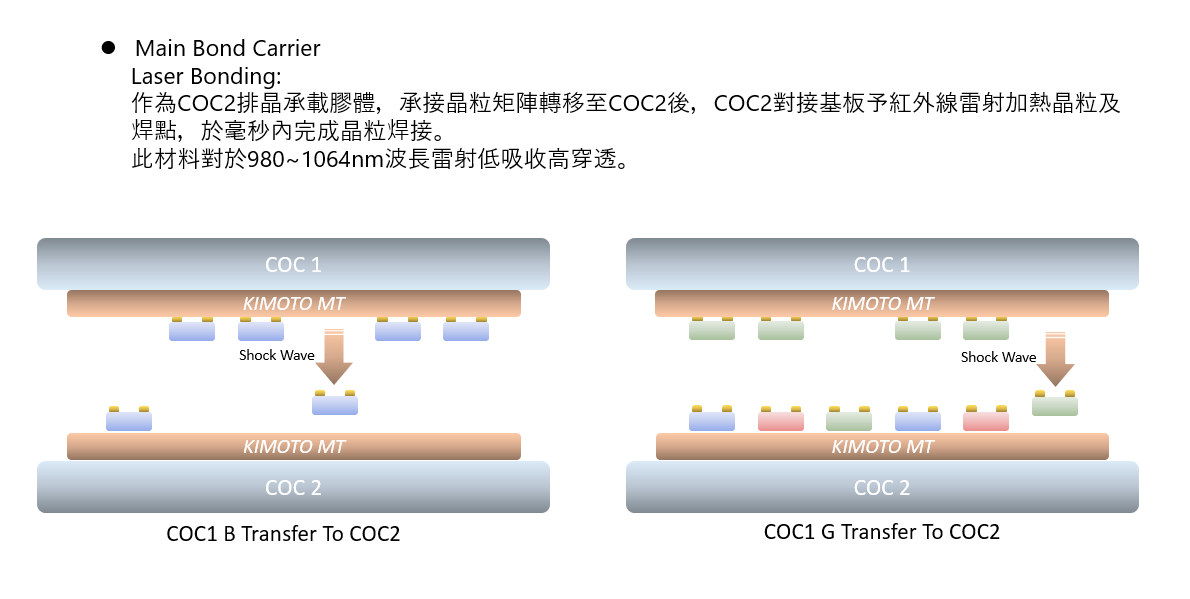

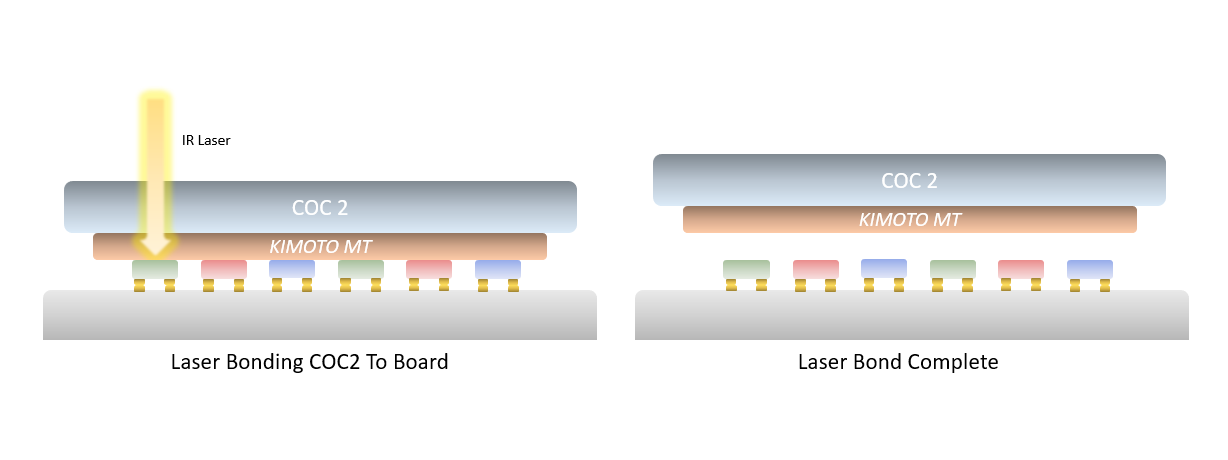

Main Bond Carrier (Laser & Stamp)|Laser & Stamp

Bonding Platform

Key Features:

• Supports laser bonding at 980–1064nm wavelengths with low

absorption and high transmittance

• Compatible with infrared laser heating, enabling millisecond-scale

bonding

• Also supports stamp bonding with excellent thermal conductivity,

heat resistance, and tack stability — enhancing yield and minimizing sheet loss

Application

Scenarios:

• COC2-phase bonding process for uLED

• Dual-process platforms combining laser and planar hot press bonding

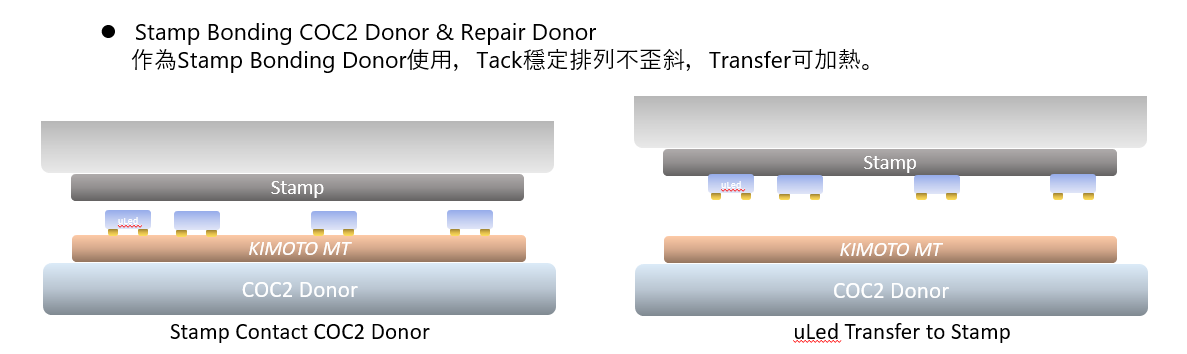

Stamp Bonding Donor Carrier|High-Stability

Alignment Carrier

Key Features:

• Delivers consistent tack value, ensuring precise chip alignment

without displacement or skew

• Suitable for thermal transfer processes in high-precision stamp

bonding

Application Scenarios:

• Stamp bonding during the COC2 phase

• Applications requiring high alignment accuracy using stamp

compression

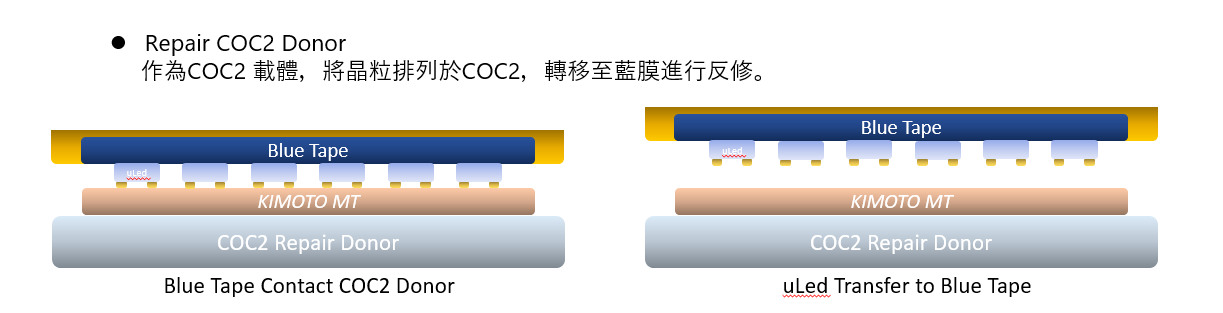

Repair Donor Film|For Precision Rework

Processes

Key Features:

• Dedicated for COC2-phase rework; supports chip alignment and

transfer to blue tape or stamp platforms

• Enables accurate chip repositioning and rework, enhancing yield

control and material utilization

Application Scenarios:

• Post-transfer rework for COC2 uLED chips

• Precision chip replacement or selective reworking operations

B-stage Sheet Encapsulation Film|For micro/Mini LED & Semiconductor Packaging

Key Features:

High-reliability encapsulation solution

designed to enhance transfer accuracy and process stability.

Application Scenarios:

Chunyang provides B-stage thermosetting

encapsulation films engineered for micro/Mini LED mass transfer and advanced

semiconductor packaging. These pre-cured films feature controlled flowability,

adhesion stability, heat resistance, and low residue, making them ideal for

multi-layer stacking, chip attach, and wafer-level packaging (WLP). The films

help improve alignment accuracy and process consistency while reducing yield

loss.

rework and packaging.

turnaround

Contact us today for a free sample or technical

white paper!